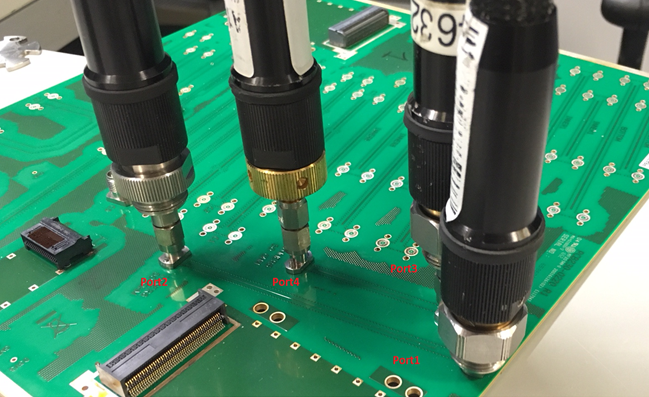

The measurement setup with a 50-GHz VNA is shown in Fig. 10. One of the first problems we faced with this piece of equipment was the very thick cables that came with it. The measurements could not be completed for the differential structures because the connectors were placed too close to each other. We substituted thinner cables, recognizing there could be a degradation of the measurement quality. The measurements came out with high formal quality metrics as shown on the right side of the Fig. 10. However, a closer look at the lower frequencies revealed the problem illustrated in Fig. 11: it looks like the reflection parameters converge to incorrect values (it should flatten at lower frequencies). An attempt to build rational approximation and use it to extrapolate data to DC failed as illustrated on the right plot in Fig. 11. (Note, that TDNA data at lower frequencies showed proper convergence.)

Figure 10. S-parameters measurement setup with 50 GHz VNA (left) and final Simbeor quality metrics (right, the metrics are in process of standardization by IEEE T370 PG3).

Figure 11. Identifying a problem with VNA measurements at lower frequencies (left), and an attempt to extrapolate the results with the rational approximation (right, stars – measured, x – rational approximation).

The VNA vendor explained the low frequency divergence is caused by the eCal calibration kit and recommended that we use a mechanical calibration kit instead. The mechanical calibration kit indeed helped, as illustrated in Fig. 12. Unfortunately, the available kit reduced the upper measurement frequency down to 26 GHz , and that was unacceptable. Thus, we used these measurements to validate the results obtained with the eCal kit and to identify the conductor resistivity only. To proceed with the data measured with eCal kit up to 50 GHz, we cut the measured data below 70 MHz as illustrated in Fig. 13.The rational approximation to DC is more realistic in this case and still indicates good quality of the remaining data, but the extrapolation to DC is not reliable. So, the data cannot be used for the copper resistivity identification. It may also lead to unreliable DC convergence on TDR and substantial problems with the eye diagram computation with such S-parameters. As stated in [7] "…a 0.5 dB error injected at a lower frequency (<10 MHz) on transmission could take an 85% open eye to a fully closed eye" – that is scary statement!

Further visual inspection of the S-parameters of the differential transmission line segments revealed big resonance in the insertion loss for the traces in layer INNER3 and smaller resonances above 30 GHz in all traces as shown in Fig. 14. The reality is that the stubs on the launches to INNER3 layer were not backdrilled, which considerably reduced the bandwidth of the GMS-parameters for layer INNER3. That is not a big problem because the material parameters identified for layer INNER2 are expected to work for the layer INNER3. (The layers are expected to be identical.)

Figure 12. S-parameters measured with 50 GHz VNA with mechanical calibration kit.

Figure 13. Possible workaround for the low frequency problem – cut the measured data below 70 MHz and use rational approximation for extrapolation.

Figure 14. Visual inspection of S-parameters for differential material identification structures.

The final goal of this stage is to have clean GMS-parameters for the material model identification. GMS parameters of 5 cm (about 2 inch) transmission line segments are computed from measured S-parameters of two segments with 5 cm (about 2 inch) and 10 cm (about 4 inch) lengths. GMS-parameters are S-parameters of the line segment in the modal space normalized to the characteristic impedances of the modes; they are reflection-less and do not have mode transformation parameters. This is the simplest form of S-parameters that can be used to identify the material properties with high accuracy [5]. GMS-parameters of differential t-line segments are 4 by 4 matrices with just 2 unique non-zero elements: modal transmission parameters for odd mode (mode 1) and even mode (mode 2). The reflection and mode transformation parameters are zero by definition. That makes it particularly attractive for material identification purposes. The complex propagation constant (Gamma) can be extracted from the GMS-parameters of a segment by taking the logarithm and dividing it by the segment length. Gamma can be used for the material identification as is done in the SPP Light technique [6]. (However, we did not do this additional step in this project. The results should be nearly identical as shown in [6].)

The final step before the extraction of GMS-parameters is to pre-qualify the line segments with the TDR. Examples of such pre-qualification are shown on the left plots of Fig.15 and 16. The impedance variations are within 2-3 Ohms that is expected to be acceptable to extract the GMS-parameters up to 25-30 GHz (see sensitivity analysis at [8]). Examples of GMS-parameters extracted for microstrip lines and strip lines in layer INNER6 are also shown in Fig. 15 and 16 on the right plots (raw data, no post-processing). Either the manufacturing variations or the launch localization or, most likely both factors, prevented the GMS-parameters extraction above 30 GHz – the insertion losses were particularly noisy above 30 GHz (not shown on the plots). Phase delays are less sensitive to the variations [8]. GMS-parameters came out as acceptable up to 30 GHz for all structures, except for the INNER3 layer. The stub resonances visible on the Fig. 14 restricted the frequency bandwidth down to 20 GHz. Fortunately, the layer INNER3 is expected to have exactly the same materials and can be used for the identification.

Figure 15. TDR for 5 cm and 10 cm diff. microstrip traces (left plot) and GMS-parameters for the odd and even modes (insertion loss and phase delay) of the 5 cm difference segment (right plot).

Figure 16. TDR for 5 cm and 10 cm diff. strip traces in layer INNER6 (left plot) and GMS-parameters for the odd and even modes (insertion loss and phase delay) of the 5 cm difference segment (right plot).

As we can see on the right plot of Fig. 15, the odd (differential) and even (common) modes have different propagation delay and attenuation that is expected for the microstrip structures (inhomogeneous dielectric). On the other hand, the strip structures in homogeneous dielectric should have nearly identical phase delay for the odd and even modes (a small difference may be due to the internal conductor inductance). However, in reality we observed some differences of the phase delay for the odd and even modes for all strip line structures on the validation board. It is clearly visible for strip layer INNER6 in the Fig. 16. That indicates that the dielectric has some inhomogeneity. The consequence of this inhomogeneity is the difference in the mode propagation that leads to the far end crosstalk (FEXT) that is expected to be nearly zero for the strip lines.

We stress that the broadband measurements of S-parameters for signal integrity purposes are particularly challenging and not all measurement equipment is suitable. SI problems require high accuracy over extremely broad bandwidth. Switching from one tool to another requires a lot of planning and preparation. It is one of the reality lessons learned in this project. At this step in our work, the GMS-parameters were successfully extracted up to 30 GHz, and that is sufficient to identify the frequency-continuous material models that are expected to work up to 40-50 GHz. Also, measurements down to 10 MHz are available, to identify the copper resistivity.

What is in the board?

Before the material parameters identification, we have to know the actual geometry of the traces for the material identification structures. As was observed in similar project [4], the actual geometry can be very far from the expectations, and the analysis results without knowing it are unreliable.

Traces on the material identification structures, launches, Beatty in INNER6, and some viaholes have been cross-sectioned as shown in Fig. 17. This is not a statistical investigation but rather validation of how far are our expectations based on the adjustments provide by the manufacturer. Analysis of the cross-sections of links in layers INNER1 is shown in Fig. 17 on the right. Analysis of the cross-sections in layer INNER6 and BOTTOM are shown in Fig. 18 and 19.

Figure 17. Validation board cross-sectioning plan (left) and example of the cross-sectioning analysis for 5 cm and 10 cm links in layer INNER1 (right).

The first observation is that the prepreg layer thickness is 3-5 um thinner than provided by the manufacturer (see Fig. 2). With that adjustment, the thickness of the interior prepreg layers becomes closer to the thickness of the core layer. That makes sense – pressed and baked prepreg should be the same material as the core if both laminates are from the same manufacturer and same batch.

The second observation is that the geometry of the strip traces is very close to the expectations. Even without the cross-sectioning, the material identification and analysis results would be very close. Though, it is totally different for the microstrips as we can see on the Fig. 18 and 19. The microstrip layer is thicker than expected, traces are narrower by about 10 um, and the trace shape is not rectangular but rather “hat” or “butterfly” shape. Also, the solder mask is very thick between the traces and thin on top of the microstrips. This is typical, but we cannot guess all that without the cross-sectioning. Analysis based on the numbers provided by the manufacturer (Fig. 1 and 2) would give the impedance lower by 2-3 Ohm and different losses (the losses depend on the trace shape).

Figure 18. Cross-sectioning analysis for 5 cm and 10 cm links in layer INNER6 (left) and in layer BOTTOM (right).

Figure 19. Close up of the cross-sectioning analysis for 5 cm (left) and 10 cm (right) links in layer BOTTOM (microstrip).

Figure 20. Width-distance-width adjustments for the differential traces and width adjustment for single ended traces (can be applied only for the impedance controlled segments).

The final trace width and distance adjustments are shown in Fig. 20. The most critical adjustments for the microstrips are highlighted in red. Also, the microstrip layer metal thickness is 48 um instead of expected 35 um, and the solder mask layer has thickness 10 um over strips and 38 um between the strips. The analysis with the microstrip geometry from the board layout or even with the adjustments obtained from the manufacturer would lead to characteristic impedance mismatch of about 3 Ohm for single-ended and about 6 Ohm for differential microstrip traces. We determined that the analysis with the trace width and spacing specified in the original layout are not acceptable to provide good accuracy below 10 GHz due to considerable impedance mismatch. The microstrip trace adjustments cannot be predicted and properly accounted for without the cross-sectioning. Though, the adjustments provided by the board manufacturer for strip layers can be safely used. In addition to traces, some via holes marked in Fig. 17 were cross-sectioned and compared with the expectations – the results are available in the complete report [9]. At this point everything is ready for the material models identification.

Material parameters identification

For material parameters identification we used measurements obtained with 50 GHz VNA and eCal calibration kit. The measurements with the mechanical calibration kit were used to identify the copper resistivity for INNER6 layer only (used for all strips). But first, let’s check the spreadsheet data from Fig. 1 and 2 and middle column in Fig. 20. The extracted reflection-less GMS parameters allow precise analysis of the model deficiencies. Generalized modal insertion loss and phase delay for differential microstrip and strip lines are shown in Fig. 21 as an example of the initial measurement-to-simulation comparison. We can observe some differences in the modal phase delays: the model predicts lower delays. This is expected due to the anisotropy of the layered laminate dielectrics (strip resonator method typically used by laminate manufacturers identifies Dk for the out-of-plane direction). More important, the measured and simulated modal insertion losses are dramatically different. Such differences make any analysis with the spreadsheet data useless above about 3 GHz - this is the reality.

Figure 21. Measured (stars) and modeled without roughness (circles) GMS insertion loss and phase delay for 5 cm differential segment in layers BOTTOM (left plot, microstrips) and INNER6 (right plot, strips).

There are multiple ways to proceed with the material models identification (see overview in [4] and [5]). Typically, raw or de-embedded S-parameters are used to “tune” a corresponding model (sometimes called “model calibration”). This is an acceptable technique, but it is too complicated due to a large number of non-zero S-parameters in the case of differential traces. The simplest way is to use just two GMS-parameters and the following formal process (identification with dielectric and conductor loss separation):

- Identify copper resistivity by matching measured and simulated GMS insertion loss (GMS IL) at the lowest frequencies;

- Identify dielectric constant (Dk) by matching measured and simulated GMS phase delay (GMS PD);

- Identify loss tangent by matching GMS IL at lower frequencies (below 1-2 GHz) and re-adjust Dk to match GMS PD (changes in LT can affect the delay);

- Identify roughness model parameters by matching GMS IL at high frequencies (above 2-3 GHz) and re-adjust Dk to match GMS PD (roughness can also affect the delay);

- Do it for all unique dielectrics in the stackup

There are three ways to proceed with the material identification for this stackup. The simplest way is to assume that the dielectric filling of the layers INNER1/INNER6 and INNER2/INNER3 are homogeneous. After all, the cured prepreg should be about the same dielectric as the core. The identified Wideband Debye models with Dk and LT @ 1 GHz (data from the spreadsheet are in the brackets) are as follows: INNER1/INNER6: Dk=3.45 (3.23 & 3.37), LT=0.0035 (0.002); INNER2/INNER3: Dk=3.4 (3.19 & 3.37), LT=0.003 (0.002). The conductor surface roughness for all strip layers is identified as one-level Modified Hammerstad model with SR=0.35 um and RF=2.5. It is just two dielectric models – relatively easy to identify and suitable for the analysis of vias and launches, but it compromises the accuracy of trace analysis. In particular, use of non-causal roughness models results in the differential strip impedance lower than observed on TDR by 2-3 Ohm. Also, the use of a homogeneous dielectric for each strip layer results in no difference in phase delay of the even and odd modes and zero far end crosstalk.

Figure 22. Two possible outcomes of the material model identification – with core and prepreg layers (left) and with additional resin-rich layer around each strip layer, to account for FEXT (right).

Another option is to stick with the core/prepreg stackup structure and identify one model for the core dielectric and three models for the strip prepreg layers as shown in Fig. 22 on the left. The identified Wideband Debye models with Dk and LT @ 1 GHz (spreadsheet data for comparison are in the brackets): CORE (all layers, 1035 weave): Dk=3.37 (3.37), LT=0.003 (0.002); Prep. INNER1/INNER6 (1027 weave): Dk=3.37 (3.23), LT=0.003 (0.002); Prep. INNER2 (1035 weave): Dk=3.27 (3.19), LT=0.002 (0.002); Prep. INNER3 (1035 weave): Dk=3.25 (3.19), LT=0.002 (0.002). In this case causal Huray-Bracken models with parameters SR=0.098 um, RF=12.5 are used for all strip layers, to account for the difference of the impedances observed on the preliminary TDR comparison. Conductor resistivity was adjusted to 1.2 of the resistivity or the annealed copper. The prepreg and core dielectric parameters came close to the spreadsheet data in this case. However, this model has practically the same limitation as the first homogeneous dielectric model. There will be too small difference in the propagation velocity for the odd and even modes in the differential strip lines, to account for the FEXT observed in the measurements (see validation section below).

Finally, to account for the anisotropy of the layered dielectric, additional resin-rich layers around the strips were defined in the stackup as shown in Fig. 22 on the right. “Resin-rich” in this context does not mean that this is a resin layer. It may contain different components that make properties of this composite material different from the layer with the fabric. The identified Wideband Debye models with Dk and LT @ 1 GHz (original values are in the brackets): CORE (all layers): Dk=3.37 (3.37), LT=0.003 (0.002); Prep. INNER1/INNER6: Dk=3.17 (3.23), LT=0.003 (0.002); Resin INNER1/INNER6: Dk=3.562, LT=0.003; Prep. INNER2: Dk=3.124 (3.19), LT=0.002 (0.002); Prep. INNER3: Dk=3.09 (3.19), LT=0.002 (0.002); Resin INNER2/INNER3: Dk=3.425, LT=0.002. The conductor and conductor roughness models are the same as for the previous case. The material parameters for the microstrip layer were the same for the last two cases with Dk=3.4 (3.19), LT=0.006 (0.002) for prepreg and Dk=3.2 (4.0), LT=0.02 for the solder mask (both Wideband Debye models @ 1 GHz). Causal Huray-Bracken model parameters for microstrip are SR=0.229 um, RF=3.77.

Figure 23. Measured (stars) and simulated (x-s) GMS insertion loss (IL) and phase delay (PD) for differential transmission lines in all unique layers.

Figure 24. Measured and simulated odd and even mode phase delays for traces in layers INNER2 and INNER6.

Correspondence of the measured and identified GMS-parameters is shown in Fig. 23. The advantage of the model with the resin-rich layer around the strips is illustrated in Fig. 24. Without the additional layer, phase delays of the even and odd modes are much closer to each other, and the FEXT in the model is almost zero, even with different core and prepreg models. Everything looks good now, and we are ready to proceed with the validation step.

Validation: expectations vs. reality

At the validation step, we simulated all structures on the board with the trace width and shape adjustments identified earlier and dielectric and conductor roughness models identified in the previous section. The layered dielectric structure with the “resin-rich” layer is going to be used as the most accurate. No further adjustments are allowed at this step. The goal here is not getting a good fit between the measurements and models by tuning the model parameters and showing that we can achieve excellent correlation, but rather see what accuracy can be achieved based on the formal material identification and limited number of cross-sections. This is the most important step to have confidence in the manufacturing, measurements and modeling or reveal the problems.

To start the validation, we have to decide what is going to be modeled. There are two options: either de-embed connectors and launches from the measured data (simpler models) or create models of the measured links with the coaxial connectors and launches. De-embedding on PCBs is notoriously difficult due to the manufacturing variations [1]. It may distort some measurements (for low reflective structures) and also reduces the frequency bandwidth. We will use it only for high-reflective structures, such as Beatty standard. The low-reflective structures are simulated with the connectors and launches. The connector models were not available. To overcome this obstacle, the model of the connector was simply synthesized from S-parameters measured for two connectors connected symmetrically back-to-back. We used cascaded connection of two coaxial sections to model the connector and then matched both the magnitude and phase of the reflection and transmission of the measured S-parameters and the circuit model of the back-to-back structure. In addition, models for all launches (PCB part) were built with the 3D electromagnetic analysis as a part of the post-layout electromagnetic de-compositional analysis in Simbeor.

Considering what to compare, technically, the comparison of the magnitudes and phases of S-parameters is sufficient to make a decision on accuracy or spot a problem. Though, comparison in the time domain is usually also needed as it may reveal additional problems. Comparison with TDR/TDT response that is measured directly with a TDR scope requires modeling the step function with the shape and spectrum matching the one used in the experiment. It is a similar situation with the eye diagrams. Using the ideal ramp step functions or PRBS with ideal trapezoidal shaped pulses may obfuscate and distort the results. Alternatively, measured and modeled S-parameters should be used to do all time domain computations with exactly the same stimuli matching the bandwidth of the model. It can be done in two ways: either with convolution with the impulse response computed directly from discrete S-parameters with IFFT or with the rational approximation and fast recursive convolution as it is done here. The rational approximation is frequency-continuous and naturally extends S-parameters to DC and to infinite frequencies. It is also causal by definition if passivity is ensured. The accuracy of the time domain analysis in this case is defined only by the accuracy of the rational approximation. In other words, the accuracy is always under control, unlike in the case of analysis with IFFT where interpolation and extrapolation introduce uncontrolled errors. In addition, the recursive convolution is exact for piecewise linear signals and much faster than the direct convolution. Thus, we will naturally use the rational approximation for all time-domain computations here. After all decisions on the modeling are made, we run the post-layout analysis for all structures on the validation board and compare the magnitudes of S-parameters, phase delays, TDR computed with Gaussian step with 20 ps 10-90% rise time and eye diagrams computed with 30 Gbps NRZ PRBS signal with 25 ps rise and fall time generated with LFSR with order 32.

First we simulated the differential links used to extract GMS-parameters at the material model identification step, to see how the model scales for longer segments. Fig. 25 illustrates the analysis of the complete 10 cm (about 4 inch) differential strip link in layer INNER6 with the de-compositional electromagnetic analysis in Simbeor software. The link is divided into single-ended and differential microstrip segments and connector + launch discontinuities at four ends. The results of the validation are shown in Fig. 26-28. Measured and modeled magnitudes of the single-ended S-parameters are compared in Fig. 26. There is good correspondence in the insertion loss, FEXT (due to matching odd and even modes as shown in Fig. 24) and NEXT up to about 30 GHz (what is going on above 30 GHz is explained later). Though we can see some differences in the reflection parameter starting from about 10 GHz and having impact on the insertion loss around 30 GHz.

Figure 25. De-compositional electromagnetic model of the diferential. strip link in layer INNER6 (Simbeor).

Figure 26. 10 cm differential strip link in layer INNER6 – measured and modeled magnitudes of single-ended S-parameters.

Figure 27. 10 cm diferential. strip link in layer INNER6 – measured and modeled mixed-mode S-parameters magnitude (left plot) and phase delay for diff. and common mode transmission parameters (right plot).

Figure 28. 10 cm differential strip link in layer INNER6 – single-ended (left plot) and mixed-mode (right plot) measured and modeled TDRs.